| 1.6MPa | |||||||||||||||||||||||

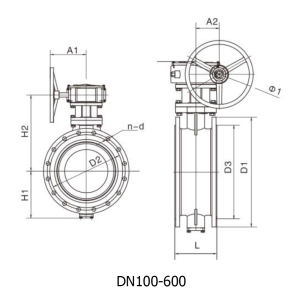

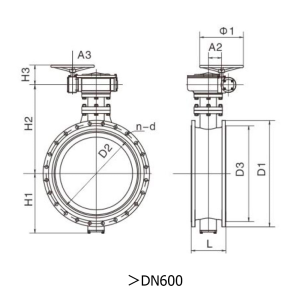

| DN | D1 | D2 | D3 | L | L2 | b | n-d | H1 | H2 | H3 | H4 | H5 | A1 | A2 | A3 | A4 | A5 | Φ1 | Φ2 | Number of opening and closing cycles | Weight(kg) | ||

| length | expansion | steel | iron | ||||||||||||||||||||

| 100 | 220 | 180 | 156 | 127 | 190 | ±15 | 22 | 19 | 8-Φ18 | 130 | 230 | 260 | 190 | 155 | 44 | 126 | 68 | 180 | 200 | 8 | 23 | ||

| 125 | 250 | 210 | 184 | 140 | 200 | ±15 | 22 | 19 | 8-Φ18 | 145 | 250 | 280 | 190 | 155 | 44 | 126 | 68 | 180 | 200 | 28 | |||

| 150 | 285 | 240 | 211 | 140 | 210 | ±15 | 24 | 19 | 8-Φ22 | 165 | 270 | 300 | 190 | 155 | 44 | 126 | 68 | 180 | 200 | 40 | |||

| 200 | 340 | 295 | 266 | 152 | 230 | ±15 | 24 | 20 | 12-Φ22 | 200 | 325 | 365 | 200 | 195 | 64 | 209 | 110 | 240 | 400 | 10 | 55 | ||

| 250 | 405 | 355 | 319 | 165 | 250 | 士15 | 26 | 22 | 12-Φ26 | 230 | 385 | 220 | 415 | 200 | 235 | 94 | 145 | 250 | 110 | 320 | 400 | 12 (single stage) 15 (pipe network) |

80 |

| 300 | 460 | 410 | 370 | 178 | 270 | ±15 | 28 | 25 | 12-Φ26 | 256 | 415 | 220 | 445 | 200 | 235 | 94 | 145 | 250 | 110 | 320 | 400 | 100 | |

| 350 | 520 | 470 | 429 | 190 | 290 | ±20 | 30 | 27 | 16-Φ26 | 292 | 495 | 240 | 540 | 210 | 275 | 132 | 196 | 250 | 140 | 400 | 500 | 14 (single stage) 21 (pipe network) |

165 |

| 400 | 580 | 525 | 480 | 216 | 310 | 士20 | 32 | 28 | 16-Φ30 | 322 | 525 | 240 | 575 | 210 | 275 | 132 | 196 | 250 | 140 | 400 | 500 | 195 | |

| 450 | 640 | 585 | 548 | 222 | 330 | ±20 | 34 | 30 | 20-Φ30 | 360 | 595 | 270 | 630 | 210 | 425 | 185 | 244 | 250 | 140 | 500 | 500 | 48 | 295 |

| 500 | 715 | 650 | 609 | 229 | 350 | ±25 | 36 | 32 | 20-Φ33 | 420 | 635 | 270 | 652 | 210 | 425 | 185 | 244 | 250 | 140 | 500 | 500 | 360 | |

| 600 | 840 | 770 | 720 | 267 | 390 | ±30 | 38 | 36 | 20-Φ36 | 465 | 705 | 270 | 740 | 210 | 425 | 185 | 244 | 250 | 140 | 500 | 500 | 470 | |

| 700 | 910 | 840 | 794 | 292 | 430 | ±30 | 38 | 40 | 24-Φ36 | 510 | 785 | 324 | 350 | 514 | 233 | 293 | 555 | 625 | 600 | 305 | 48 | 660 | |

| 800 | 1025 | 950 | 901 | 318 | 470 | ±35 | 38 | 43 | 24-Φ39 | 580 | 851 | 324 | 350 | 514 | 233 | 293 | 555 | 625 | 600 | 305 | 845 | ||

| 900 | 1125 | 1050 | 1001 | 330 | 510 | ±35 | 40 | 47 | 28-Φ39 | 632 | 975 | 360 | 375 | 590 | 296 | 350 | 650 | 305 | 57.6 | 1140 | |||

| 1000 | 1255 | 1170 | 1112 | 410 | 550 | ±40 | 42 | 50 | 28-Φ42 | 735 | 1040 | 360 | 375 | 590 | 296 | 350 | 650 | 705 | 600 | 305 | 1455 | ||

| 1200 | 1485 | 1390 | 1328 | 470 | 630 | ±40 | 48 | 57 | 32-Φ48 | 856 | 1261 | 450 | 405 | 752 | 410 | 460 | 765 | 935 | 720 | 305 | 90 | 2550 | |

| 1400 | 1685 | 1590 | 1530 | 530 | 710 | ±50 | 52 | 60 | 36-Φ48 | 995 | 1460 | 355 | 435 | 355 | 495 | 370 | 970 | 970 | 720 | 460 | 123 | 3895 | |

| 1600 | 1930 | 1820 | 1750 | 600 | 790 | ±50 | 58 | 65 | 40-Φ56 | 1170 | 1624 | 355 | 435 | 355 | 495 | 370 | 970 | 970 | 720 | 460 | 4950 | ||

| 1800 | 2130 | 2020 | 1950 | 670 | 62 | 70 | 44-Φ56 | 1320 | 1850 | 430 | 520 | 430 | 630 | 424 | 1250 | 1460 | 900 | 610 | 340 | 7500 | |||

| 2000 | 2345 | 2230 | 2150 | 760 | 66 | 75 | 48-Φ62 | 1460 | 1990 | 430 | 520 | 130 | 630 | 424 | 250 | 460 | 900 | 610 | 9500 | ||||

| 2200 | 2555 | 2440 | 2360 | 800 | 75 | 90 | 52-Φ62 | 1520 | 1910 | 430 | 1200 | 690 | 730 | 1335 | 615 | 200 | 450 | 450 | |||||

| 2400 | 2765 | 2650 | 2570 | 900 | 80 | 96 | 56-Φ62 | 655 | 2070 | 430 | 1200 | 690 | 730 | 1335 | 615 | 1200 | 450 | 450 | |||||

| 2600 | 2965 | 2850 | 2770 | 1000 | 85 | 102 | 60-Φ62 | 1790 | 2220 | 580 | 1600 | 840 | 890 | 1550 | 1850 | 1200 | 600 | 1071 | |||||

Note: Technical specifications may change without notice due to ongoing technological advancements.