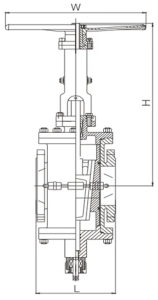

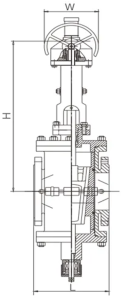

| Double Block and Bleed (DBB) Plug Valve Reduced Bore Technical Parameters | ||||||||||||||||

| TG4X-150LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | |

| H | 230 | 260 | 300 | 340 | 380 | 435 | 460 | 490 | 525 | 570 | 625 | 700 | 780 | 870 | 980 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

| TG4X-300LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 140 | 152 | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | |

| H | 230 | 260 | 300 | 340 | 380 | 435 | 460 | 490 | 525 | 570 | 625 | 700 | 780 | 870 | 980 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

| TG4X-600LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 230 | 260 | 300 | 340 | 380 | 435 | 460 | 490 | 525 | 570 | 625 | 700 | 780 | 870 | 980 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

Note: Technical specifications may change without notice due to ongoing technological advancements.