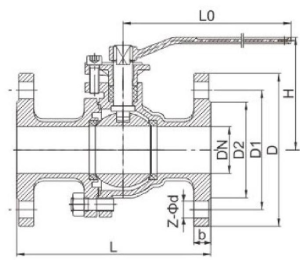

| DN | L | D | D1 | D2 | b | Z-Φd | H | L0 | |

| PN16 | |||||||||

| 15 | 130 | 95 | 65 | 45 | 14 | 4-Φ14 | 78 | 140 | |

| 20 | 130 | 105 | 75 | 55 | 14 | 4-Φ14 | 84 | 160 | |

| 25 | 140 | 115 | 85 | 65 | 14 | 4-Φ14 | 95 | 180 | |

| 32 | 165 | 135 | 100 | 78 | 16 | 4-Φ18 | 150 | 250 | |

| 40 | 165 | 145 | 110 | 85 | 16 | 4-Φ18 | 150 | 300 | |

| 50 | 203 | 160 | 125 | 100 | 16 | 4-Φ18 | 170 | 350 | |

| 65 | 222 | 180 | 145 | 120 | 18 | 4-Φ18 | 195 | 350 | |

| 80 | 241 | 195 | 160 | 135 | 20 | 8-Φ18 | 215 | 400 | |

| 100 | 305 | 215 | 180 | 155 | 20 | 8-Φ18 | 250 | 500 | |

| 125 | 356 | 245 | 210 | 185 | 22 | 8-Φ18 | 265 | 600 | |

| 150 | 394 | 280 | 240 | 210 | 24 | 8-Φ23 | 270 | 800 | |

| 200 | 457 | 335 | 295 | 265 | 24 | 12-Φ23 | 330 | 800 | |

| 250 | 533 | 405 | 355 | 320 | 26 | 12-Φ25 | 450 | 1300 | |

| DN | L | D | D1 | D2 | b | Z-Φd | H | L0 | |

| PN25 | |||||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 4-Φ14 | 103 | 100 | |

| 20 | 140 | 105 | 75 | 55 | 16 | 4-Φ14 | 112 | 160 | |

| 25 | 150 | 115 | 85 | 65 | 16 | 4-Φ14 | 123 | 160 | |

| 32 | 165 | 135 | 100 | 78 | 18 | 4-Φ18 | 150 | 250 | |

| 40 | 180 | 145 | 110 | 85 | 18 | 4-Φ18 | 156 | 250 | |

| 50 | 200 | 160 | 125 | 100 | 20 | 4-Φ18 | 172 | 350 | |

| 65 | 220 | 180 | 145 | 120 | 22 | 8-Φ18 | 197 | 350 | |

| 80 | 250 | 195 | 160 | 135 | 22 | 8-Φ18 | 222 | 450 | |

| 100 | 280 | 230 | 190 | 160 | 24 | 8-Φ23 | 253 | 450 | |

| 125 | 320 | 270 | 220 | 188 | 28 | 8-Φ25 | 275 | 600 | |

| 150 | 360 | 300 | 250 | 218 | 30 | 8-Φ25 | 286 | 800 | |

| 200 | 400 | 360 | 310 | 278 | 34 | 12-Φ25 | 340 | 1200 | |

| 250 | 530 | 425 | 370 | 332 | 36 | 12-Φ30 | 470 | 1400 | |

| DN | L | D | D1 | D2 | b | Y | Z-Φd | H | L0 |

| PN40 | |||||||||

| 15 | 140 | 95 | 65 | 45 | 16 | 40 | 4-Φ14 | 103 | 100 |

| 20 | 152 | 105 | 75 | 55 | 16 | 51 | 4-Φ14 | 112 | 160 |

| 25 | 165 | 115 | 85 | 65 | 16 | 58 | 4-Φ14 | 123 | 160 |

| 32 | 178 | 135 | 100 | 78 | 18 | 66 | 4-Φ18 | 150 | 250 |

| 40 | 190 | 145 | 110 | 85 | 18 | 76 | 4-Φ18 | 156 | 250 |

| 50 | 216 | 160 | 125 | 100 | 20 | 88 | 4-Φ18 | 172 | 350 |

| 65 | 241 | 180 | 145 | 120 | 22 | 110 | 8-Φ18 | 197 | 350 |

| 80 | 283 | 195 | 160 | 135 | 22 | 121 | 8-Φ18 | 222 | 450 |

| 100 | 305 | 230 | 190 | 160 | 24 | 150 | 8-Φ23 | 253 | 450 |

| 125 | 381 | 270 | 220 | 188 | 28 | 176 | 8-Φ25 | 275 | 600 |

| 150 | 403 | 300 | 250 | 218 | 30 | 204 | 8-Φ25 | 286 | 800 |

| 200 | 502 | 375 | 320 | 282 | 38 | 260 | 12-Φ30 | 340 | 1200 |

| 250 | 568 | 445 | 385 | 345 | 42 | 313 | 12-Φ34 | 470 | 1400 |

Note: Technical specifications may change without notice due to ongoing technological advancements.