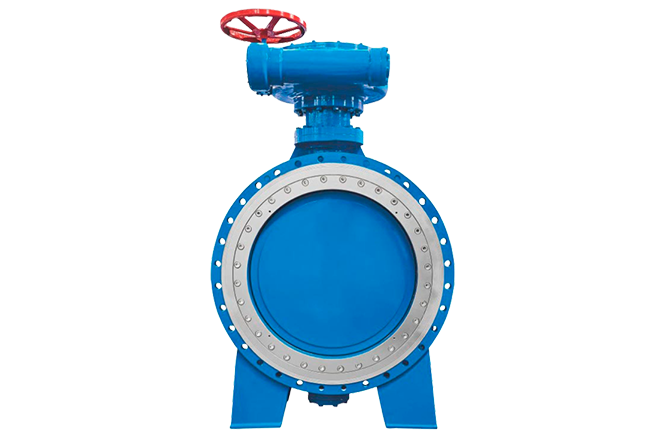

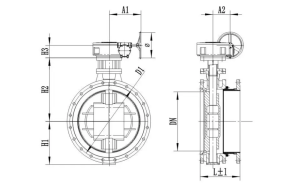

| DQ342H-2.5/6/10/16 Flanged Telescopic Rotary Butterfly Valve Dimensions | ||||||||||||||||

| DN | L | Expansion △L | H1 | H2 | H3 | A1 | A2 | Φ | 0.25MPa | 0.6MPa | 1.0MPa | 1.6MPa | ||||

| D1 | n-d | D1 | n-d | D1 | n-d | D1 | n-d | |||||||||

| 50 | 150 | ±10 | 82.5 | 150 | 66 | 135 | 42 | 150 | 110 | 4-Φ14 | 110 | 4-Φ14 | 125 | 4-Φ19 | 125 | 4-Φ19 |

| 65 | 170 | ±10 | 92.5 | 165 | 66 | 135 | 42 | 150 | 130 | 4-Φ14 | 130 | 4-Φ14 | 145 | 4-Φ19 | 145 | 4-Φ19 |

| 80 | 180 | ±10 | 100 | 170 | 66 | 135 | 42 | 150 | 150 | 4-Φ19 | 150 | 4-Φ19 | 160 | 8-Φ19 | 160 | 8-Φ19 |

| 100 | 190 | ±10 | 125 | 195 | 11 | 135 | 42 | 180 | 170 | 4-Φ19 | 170 | 4-Φ19 | 180 | 8-Φ19 | 180 | 8-Φ19 |

| 125 | 200 | ±10 | 142 | 220 | 77 | 135 | 42 | 180 | 200 | 8-Φ19 | 200 | 8-Φ19 | 210 | 8-Φ19 | 210 | 8-Φ19 |

| 150 | 210 | ±10 | 160 | 250 | 77 | 135 | 42 | 320 | 225 | 8-Φ19 | 225 | 8-Φ19 | 240 | 8-Φ23 | 240 | 8-Φ23 |

| 200 | 230 | ±12 | 190 | 275 | 107 | 202 | 60 | 320 | 280 | 8-Φ19 | 280 | 8-Φ19 | 295 | 8-Φ23 | 295 | 12-Φ23 |

| 250 | 250 | ±12 | 220 | 305 | 107 | 202 | 60 | 320 | 335 | 12-Φ19 | 335 | 12-Φ19 | 350 | 12-Φ23 | 355 | 12-Φ28 |

| 300 | 270 | ±15 | 245 | 350 | 126 | 220 | 93 | 320 | 395 | 12-Φ23 | 395 | 12-Φ23 | 400 | 12-Φ23 | 410 | 12-Φ28 |

| 350 | 290 | ±15 | 278 | 385 | 126 | 220 | 93 | 320 | 445 | 12-Φ23 | 445 | 12-Φ23 | 460 | 16-Φ23 | 470 | 16-Φ28 |

| 400 | 310 | ±15 | 305 | 435 | 157 | 287 | 123 | 400 | 495 | 16-Φ23 | 495 | 16-Φ23 | 515 | 16-Φ28 | 525 | 16-Φ31 |

| 450 | 330 | ±15 | 346 | 490 | 157 | 287 | 123 | 400 | 550 | 16-Φ23 | 550 | 15-Φ23 | 565 | 20-Φ28 | 585 | 20-Φ31 |

| 500 | 350 | ±20 | 375 | 505 | 165 | 360 | 184 | 390 | 600 | 20-Φ23 | 600 | 20-Φ23 | 620 | 20-Φ28 | 650 | 20-Φ34 |

| 600 | 390 | ±20 | 425 | 605 | 165 | 360 | 184 | 390 | 705 | 20-Φ26 | 705 | 20-Φ26 | 725 | 20-Φ31 | 770 | 20-Φ37 |

| 700 | 430 | ±20 | 495 | 675 | 195 | 410 | 204 | 500 | 810 | 24-Φ26 | 810 | 2-Φ26 | 840 | 24-Φ31 | 840 | 24-Φ37 |

| 800 | 470 | ±30 | 560 | 740 | 195 | 410 | 204 | 500 | 920 | 24-Φ31 | 920 | 24-Φ31 | 950 | 24-Φ34 | 950 | 24-Φ40 |

| 900 | 510 | ±30 | 625 | 805 | 235 | 521 | 217 | 500 | 1020 | 24-Φ31 | 1020 | 24-Φ31 | 1050 | 28-Φ34 | 1050 | 28-Φ40 |

| 1000 | 550 | ±30 | 680 | 865 | 235 | 521 | 217 | 500 | 1120 | 28-Φ31 | 1120 | 28-Φ31 | 1160 | 28-Φ37 | 1170 | 28-Φ43 |

| 1200 | 630 | ±35 | 800 | 1065 | 251 | 501 | 290 | 630 | 1320 | 32-Φ31 | 1340 | 32-Φ34 | 1380 | 32-Φ40 | 1390 | 32-Φ49 |

| 1400 | 710 | ±35 | 920 | 1207 | 343 | 656 | 312 | 800 | 1520 | 36-Φ31 | 1560 | 36-Φ37 | 1590 | 36-Φ43 | 1590 | 36-Φ49 |

| 1600 | 790 | ±40 | 1030 | 1317 | 370 | 750 | 414 | 800 | 1730 | 40-Φ31 | 1760 | 40-Φ37 | 1820 | 40-Φ49 | 1820 | 40-Φ56 |

| 1800 | 870 | ±40 | 1245 | 1457 | 470 | 800 | 440 | 900 | 1930 | 44-Φ31 | 1970 | 44-Φ40 | 2020 | 44-Φ48 | 2020 | 44-Φ56 |

| 2000 | 950 | ±50 | 1290 | 1625 | 470 | 800 | 440 | 900 | 2130 | 48-Φ30 | 2180 | 48-Φ43 | 2230 | 48-Φ48 | 2230 | 48-Φ62 |

| 2200 | 1000 | ±50 | 1450 | 1740 | 470 | 800 | 440 | 900 | 2340 | 52-Φ33 | 2390 | 52-Φ43 | 2440 | 52-Φ56 | 2440 | 52-Φ62 |

| 2400 | 1100 | ±50 | 1675 | 1875 | 480 | 990 | 595 | 1000 | 2540 | 56-Φ33 | 2600 | 56-Φ43 | 2650 | 56-Φ56 | 2650 | 56-Φ62 |

| 2600 | 1200 | ±50 | 1745 | 2010 | 480 | 990 | 595 | 1000 | 2740 | 60-Φ33 | 2810 | 60-Φ48 | 2850 | 60-Φ55 | 2850 | 60-Φ62 |

| 2600 | 1200 | ±50 | 1745 | 2010 | 480 | 990 | 595 | 1000 | 2740 | 60-Φ33 | 2810 | 60-Φ48 | 2850 | 60-Φ55 | 2850 | 60-Φ62 |

| 3000 | 1400 | ±50 | 1910 | 2200 | 480 | 990 | 595 | 1000 | 3160 | 68-Φ36 | 3220 | 68-Φ48 | 3290 | 68-Φ62 | 3300 | 68-Φ70 |

Note: Technical specifications may change without notice due to ongoing technological advancements.