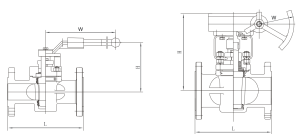

| Main dimensions | ||||||||||||||||

| X343F/X43F-150LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 620 | 680 | 760 | |

| W | 195 | 205 | 205 | 315 | 315 | 330 | 400 | 590 | 690 | 300 | 320 | 320 | 350 | 380 | 450 | |

| (Kg)Weight | 8.5 | 9.5 | 10.5 | 12 | 14 | 18 | 22 | 26 | 40 | 60 | 70 | 130 | 219 | 381 | 570 | |

| X343F/X43F-300LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 140 | 152 | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 502 | 580 | 620 | 680 | 760 | |

| W | 195 | 205 | 205 | 315 | 315 | 330 | 400 | 590 | 690 | 300 | 320 | 320 | 350 | 380 | 450 | |

| (Kg)Weight | 8.5 | 9.5 | 10.5 | 12 | 14 | 18 | 22 | 26 | 40 | 60 | 70 | 130 | 219 | 381 | 570 | |

| X343F/X43F-600LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 620 | 680 | 760 | |

| W | 195 | 205 | 205 | 315 | 315 | 330 | 400 | 590 | 690 | 300 | 320 | 320 | 350 | 380 | 450 | |

| (Kg)Weight | 11 | 13 | 17 | 20 | 23 | 27 | 31 | 36 | 98 | 141 | 245 | 330 | 515 | 710 | ||

| X343F/X43F-900LB | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 216 | 229 | 254 | 279 | 305 | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 620 | 680 | 760 | |

| W | 195 | 205 | 205 | 315 | 315 | 330 | 400 | 590 | 690 | 300 | 320 | 320 | 350 | 380 | 450 | |

| (Kg)Weight | 13 | 16 | 21 | 24 | 28 | 32 | 40 | 47 | 91 | 117 | 165 | 285 | 420 | 610 | 860 | |

Note: Technical specifications may change without notice due to ongoing technological advancements.