According to the differences in butterfly valve structure, butterfly valves can be divided into four types, they are concentric butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve. What is the concept of eccentricity? How to decide when to use concentric butterfly valve, when to use single eccentric butterfly valve, and when to use double eccentric butterfly valve and triple eccentric butterfly valve? Many users are not very clear. Let's share together.

Concentric butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve, in fact, they reflect a process of opening and closing with less and less effort, and less and less wear on the sealing surface. By setting the position of the butterfly valve disc shaft, the sealing and opening states of the butterfly valve are changed. Under the same conditions, the torque applied to the valve at each opening is larger and larger. when the valve is opened ,the angle required for the valve disc to separate from the seal is smaller and smaller.

The structural feature of the concentric butterfly valve is that the valve stem axis, the center of the butterfly plate, and the center of the valve body are in the same place. Generally speaking, in principle, concentric butterfly valves should be used as much as possible. Because the sealing requirements of concentric butterfly valves are not high in both structure and operation, they are common products. In order to overcome extrusion、scratching and ensure sealing performance, the valve seat of the concentric butterfly valve is basically made of elastic materials such as rubber or polytetrafluoroethylene, so it is a soft-sealed butterfly valve. This limits the use of the concentric butterfly valve by temperature. For the purpose of solving the extrusion problem between the butterfly plate and the valve seat of the concentric butterfly valve, the single eccentric butterfly valve is also produced. Its structural feature is that the valve stem axis deviates from the center of the butterfly plate.

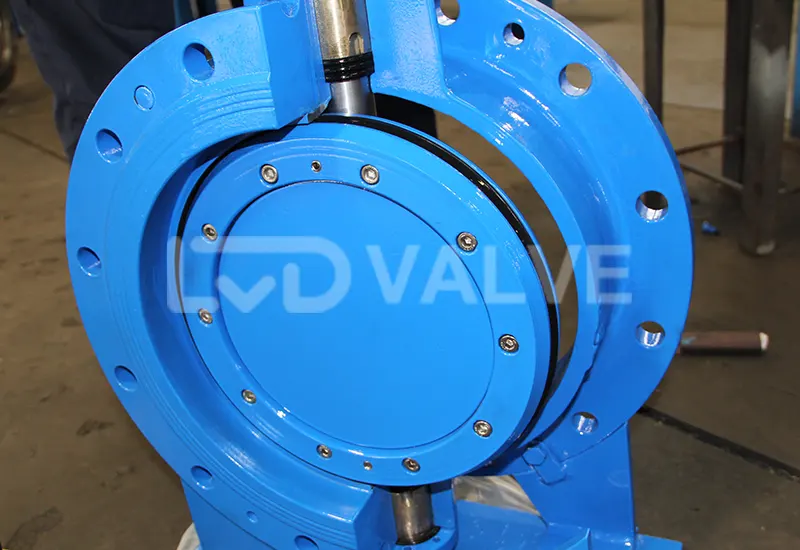

Double eccentric butterfly valve is used the most widely. Its structural feature is that the valve stem axis deviates from both the center of the butterfly plate and the center of the valve body. It is called a double eccentric butterfly valve because it deviates from two center positions. Many double eccentric butterfly valves are line seals. When the sealing surface is closed, friction is generated between the disc plate and the valve seat, and the sealing effect is very good. It has the characteristics of small area and high pressure. After the valve is opened , the butterfly plate can leave the valve seat quickly, so it can eliminate the unnecessary excessive extrusion and scraping between the butterfly plate and the valve seat to a great extent, can also reduce the opening resistance, reducing wear, and increase the life of the valve seat.

Triple eccentric butterfly valve has a third eccentricity based on the double eccentric butterfly valve. The shape of the sealing pair is not a positive cone, but an oblique cone. Most of them are short-distance force and surface seals. The valve stem shaft of the three-eccentric butterfly valve is a three-section shaft structure. The two shaft sections of this three-section shaft valve stem are concentric and the center line of the center section shaft deviates from the axis of the two ends by a center distance . The butterfly plate is installed on the middle shaft section. Such an eccentric structure makes the butterfly plate double-eccentric when it is in the fully open position, and single-eccentric when the butterfly plate rotates to the closed position. Because of the effect of the eccentric shaft, on approach to closing, the butterfly plate moves a distance into the sealing cone surface of the valve seat, and the sealing surface of the butterfly plate and the valve seat coincide to achieve reliable sealing performance. It makes up for the contradiction that hard seals have poor sealing, while soft seals have good sealing effects but are not resistant to high temperatures.

How to choose these types of valves, in my opinion, we should comprehensively compare the initial purchase cost, maintenance cost and life cycle cost, on the premise of meeting the performance requirements.

For example: the triple eccentric butterfly valve has a high initial cost, but it has a longer life, so it is suitable for long-term operation in harsh working conditions.

Here I offer some typical selection examples for you:

Water treatment system (normal temperature and pressure): centerline butterfly valve (EPDM seal) + cast iron valve body.

Chemical pipeline (corrosive media): flanged three-eccentric butterfly valve (316 stainless steel valve body + PTFE seal).

Steam system (high temperature and high pressure): three-eccentric metal seal butterfly valve + electric actuator.

When to use a concentric butterfly valve and when to choose a double eccentric butterfly valve or a triple eccentric butterfly valve depends mainly on the operating conditions and budget.